A strong, decorative approach to copper cladding for both internal and external surfaces – combining three different Nordic Copper products from Aurubis – defines the redevelopment of Onslow House, a prominent commercial headquarters building in the heart of Guildford.

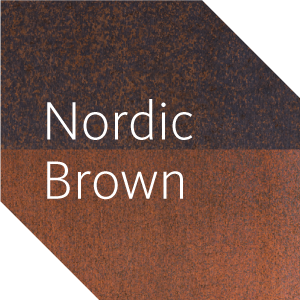

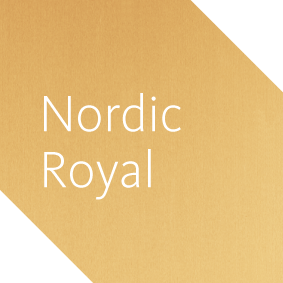

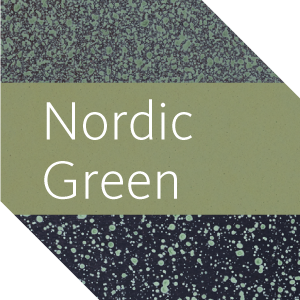

Interior design and external alterations, designed by architects AWW, sought to add value to letting space and bring the 90,600 ft² building up to date. The updated massive, glazed entrance atrium incorporates feature walls – including inset doors – faced with horizontal copper panels, alternating in three different surfaces: Nordic Standard bright ‘mill finish’, Nordic Brown Light and Nordic Brown pre-oxidised copper. The Nordic Brown range offers lighter or darker colour shades determined by the thickness of the oxide layer.

Material Continuity with Diversity

Structural columns are similarly enwrapped with alternating finish copper bands and the copper detailing is even continued into elements of bespoke furniture . The internal copper cladding had a post-lacquer finish applied to arrest further oxidisation, so retaining the three colours and protecting the surface. This creates a reflective surface, mirroring and enhancing the lightness of the atrium space. The same horizontal copper panel composition of three surfaces continues past the external glazing to the outside. Here, the building’s entrance has been transformed with new copper-clad canopies to create a strong, easily recognised identity, with minimal work to the existing building envelope.

Externally, the copper has not received a lacquer finish, as AWW explain: ‘We consider copper’s natural surface development outside, reflecting the local environment, to be one of the material’s key attributes. An attractive, gradual weathering and softening of the differentiation between the three Nordic Copper surfaces on the canopies has already begun – and will continue over time – as we anticipated.’

Fabrication and installation of the Nordic Copper panels was carried out by specialists CGL Facades.